Machining

Machining Capabilities

- Milling

- Drilling

- Boring

- Reaming

- Machining Techniques

- Subtractive

- Additive

Service Details:

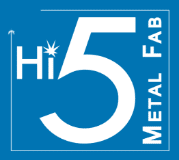

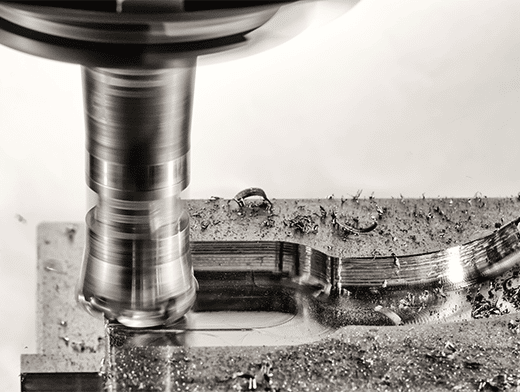

Milling - uses a rotating cutting tool to bring cutting edges to bear against the workpiece. This is the most versatile tool and technique used in a machine shop.

Drilling - creates a new hole or refines an existing hole using a rotating cutter. Drilling is most commonly done using drill presses, but sometimes drilling tools will be attached to compatible lathes or mills to create holes.

Boring - is one of the most widely used techniques in machining, as it is one of the most reliable ways to finish and enlarge pre-existing holes. This technique provides accuracy and is easily replicated on a workpiece.

Reaming - is a process that uses a rotary cutting tool to smooth an existing hole in a workpiece. This is a cutting process that removes material, and its primary purpose is to even out the walls of a hole.

Machining techniques - There are two main techniques when it comes to machining operations: subtractive and additive manufacturing. These techniques are used by a machinist to either take away or add material to a part.

Subtractive - Machining is a prototyping and manufacturing process that creates the desired shape by removing unwanted material from a larger piece of material. Since a part is built by taking away material, this process is also known as subtractive manufacturing.

Additive - Additive machining, also known as 3D printing, is a newer approach to production that enables the construction of a three-dimensional object from a digital model. It allows the machinist to create lightweight and strong parts.

Equipment

Mill

TRAK K3 Knee Mill shown

Drill Press

20" Industrial Rated Drill Press 2HP